coating test report|industrial coatings market : department Store Test Methods for Coating Adhesion. Referenced products: PosiTest AT. For coatings to perform satisfactorily, they must adhere to the substrates on which they are applied. A variety of . Curitiba Porto Alegre. 1.818 garotas de programa em Porto Alegre / POA agora diponíveis, 114 TD com escorts contados por clientes reais e 46 vídeos de acompanhantes.

{plog:ftitle_list}

Código De Segurança. Videos do OnlyFans Catarina Paolino youtuber gostosa pelada. Confiram mais um vídeo vazado da youtuber ruivinha muito gostosa Catarina Paolino se exibindo bem safadinha enquanto experimenta seus biquinis. Essa putinha ficou muito famosa no Youtube e acabou levando uma legião de seguidores para assinarem seus .

single yarn strength tester diagram solution

Hardness is a mechanical property that helps a coating resist indentation. (A wider discussion of hardness can be found in the article 5 Ways to Measure the Hardness of a Material.) A harder coating has a greater ability to withstand depressions. When indentation is a concern it is worthwhile to use a coating . See moreAbrasion of a coating occurs when all or a portion of the coating is scraped off by another material, which is clearly undesirable because . See more

The ability of a coating to adhere to a base material is extremely important because without an adequate adhesive bond, the coating could . See moreWhen coatings are applied to base materials that will undergo deformationthen it is imperative that the coating be able to . See moreTest Methods for Coating Adhesion. Referenced products: PosiTest AT. For coatings to perform satisfactorily, they must adhere to the substrates on which they are applied. A variety of .Besides the ASTM, DIN and ISO references covered in this paper, other resources are available for standardized testing and evaluation of powder coating materials: The PCI, Powder .

single yarn strength tester manufacturers solution

There are three different procedures to assess the resistance of the coating to separate from the substrate and provide different adhesion analysis of the film: cross-hatch test, scrape .Thorough documentation of each step throughout the coatings process, including presurface preparation, ambient conditions, surface profile and cleanliness, wet and dry film thicknesses, .A test procedure to evaluate the adhesive strength of the epoxy coating was developed and is recommended for quality control. The test is simple, quick, and reliable, and can be performed .Pull-off adhesion testing is a method of measuring the resistance of a coating to separation from a substrate when a perpendicular tensile force is applied. There are range of substrate .

Using the Appropriate Method: ASTM D3359 describes two test methods for evaluating tape adhesion of a coating system: Method A (X-cut Tape Test) and Method B (Cross-cut Tape Test). The method selected is based on the total .COATING ADHESION TESTING. The adhesion of a coating to a substrate may be tested according to ASTM D 4541, which covers a method for evaluating the “pull-off” strength of a .

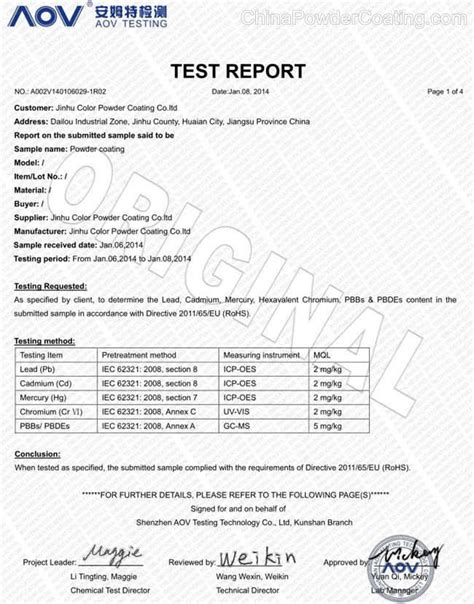

Our coatings laboratories offer a comprehensive range of testing and evaluation services covering organic and inorganic coatings such as paints, powder/fluorocarbon coatings, intumescent coatings, photocatalytic coatings, .Stainless Steel Coating Test Report Benjamin Karmiol (AMPP-3), Enkeleda Dervishi-Whetham (SIGMA-2), Michael McBride (SIGMA-2), Alexander Edgar (MST-7) 1 1. Introduction: A process was developed to coat 316L stainless steel pieces having very low levels of fixed contamination on their surface (~100 dpm/100 cm2). The coating process served to .Report 1. Weight of sample. 2. Type and thickness of glass plate. 3. Oven temperature. 4. Flow in millimeters. (1) Type and thickness of glass as agreed upon by customer and supplier. (2) Parr Calorimeter Pellet Press, Cam and Cover type, stainless steel die with . POWDER COATINGS PROCEDURE (Solvent Cure Test)conversion coating against both 6061 and 5052 aluminum under all three test conditions. Significant prior work was performed to select the aluminum and conversion coating included within this test cycle; Reference – NASA GSDO Program Hexavalent Chrome Alternatives Final Pretreatments Test Report Task Order: NNH12AA45D September 01, 2013.

Chemical Guys' Carbon Force came in a compact package with the ceramic-coating liquid, three application pads, and instructions on the back of the box. Of all the ceramic coatings we tested, it .Test Report (Primer Coating) (1) - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document summarizes an adhesion test report for a zinc phosphate primer used on a hydropower project in Ilam, Nepal. A cross-cut hatch adhesion test was performed according to ASTM D3359 standards using Scotch transparent tape.

The coating, identified by the Client as “Contego Passive Fire Barrier” Latex Intumescent Coating, was applied to a thickness of 16 mil wet on the OSB side of the wall. The assembly was built and the coating was applied by the client. 4.2. THE FIRE TEST The test wall assembly was mounted in the pilot-scale vertical furnace mounting frame.

A coating inspection test plan is crucial for ensuring the quality and performance of coatings applied to surfaces, such as in construction, manufacturing, or maintenance projects.The material used in the test is gravel of different sizes, which is projected on the coating with a defined angle using compressed air. The damage caused will depend not only on the angle but also on the pressure level, the mass of the projectiles, the duration of the bombardment and the design of the test apparatus. Commission Regulation (EU) No 10/2011 of 14 January 2011 Annex V. Report the 3rd extractive result.. German Food, Articles of Daily Use and Feed Code of September 1, 2005 (LFGB), Section 30 & 31 with amendments–Sensorial examination odour and taste test. Test Method :.With reference to DIN10955:2004,direct contact method. No.of panelist:6.stated the results shown in this test report refer only to the sample(s) tested. 25 t+886(02)2299 3939 f+886(02)2299 3237 SGS T iw Ltd:: =====::::: MAGNETICS DIVISION OF SPANG & COMPANY 110 DELTA DRIVE PITTSBURGH, PENNSYLVANIA USA 15238 MAGNETICS DIVISION OF SPANG & COMPANY POWDER CORE BLACK EPOXY COATING Test .

4.4 To prevent damage to a coating film when using high voltage test instrumentation, total film thickness and dielectric strength in a coating system shall be considered in determining the appropriate voltage for detection of discontinuities. Atmospheric conditions shall also be considered since the voltage required for the spark to gap a given .ASTM G-154 Cyclic QUV/Condensation Test Report: Two series of 10 panels were supplied to Ferro Corp. for ASTM G154 Cyclic QUV/Condensation Testing. The panels were prepared and provided by Dalton Ent. The ten series were labeled as follows: Tournament Blue, Blue, Light Blue, Red, Beige, Tournament Green, Dark Green, Light Green, Gray, Brown Where V=the test voltage and d=the coating thickness . ASTM G62 test reports shall contain: • Complete identification of the test specimen, (names/code number of the coating, pipe diameter, source, production data, and production run number). For polymeric precoated corrugated steel pipe, use ASTM A742/A742M reporting requirements.

Conflicts can occur if a manufacturer and a customer of a finished good use different methods or types of instruments to determine coating thickness. This article will discuss the test methods available for determining coating thickness, common applications, and innovations in coating thickness instrumentation. Test Methods Latest Test Results . Data Report - March 8, 2021. Data Report - August 10, 2020. . To date, these products have not been registered with EPA as antiviral coatings; some are currently being used, both domestically and internationally, in combination with cleaning and disinfection methods. The overall benefit of using such products in reducing .

This painting inspection report summarizes the painting of a job. It lists the application method, area, primers, coats, weather conditions, and paint products used. It also includes checks of conditions like temperature and humidity .We make the results of these tests available so our customers can select the best coating for their specific project. Filter By: UV. Substrate Document Name Date Download; Aluminum: QUVA 5000 HOURS 6409-10: 17/08/2016: View PDF: Aluminum: QUVA 5000 HOURS 6409-10-U UV ADDITIVE PACKAGE: 17/08/2016 . Home » Substrates » Test Reports About Us.Coating thickness is an important requirement in the specification and effectiveness of hot-dip galvanizing as a corrosion protection system. However, measuring coating thickness is only one of the many specification requirements in the inspection process. The inspection of hot-dip galvanized steel is simple and quick, and the two properties of .

SGS Natural Salt Spray Test Report of Powder Coating Post. Download Zone|site map|Add to favourites| Welcome to Zhongshan Changsheng Metal Products Co,.Ltd. ZHONGSHAN CHANGSHENGShelf Specialist Since 1998 . E-mail:[email protected]. WhatsApp:+86 180 2836 2095. WeChat:+86 180 2836 2095. Home; An example of FIB cross-sectioning workflow: (a) the sample is inserted in the chamber with 0° tilt; (b) a thin layer of metal is deposited on the surface using the electron beam; (c) the stage .

powder coating report

Here are some essential tools and important tips that can help with completing quality assurance (QA) of the protective coatings inspection quality control (QC) process -- from inspector training, pre-construction meetings, data sharing and coordination, to final inspection.. Whether providing QA in person or remotely as can often be the case during the novel coronavirus disease 2019 .Coating & Painting Inspection - Fundamentals 2020 Instructor: Jurandir Primo, PE PDH Online | PDH Center 5272 Meadow Estates Drive Fairfax, VA 22030-6658 . Inspection Reports 4. Disagreements withthe Contractor 5. Non-conformance Reports NCR) Instruments for Coatings Inspection VII. DUTIES OF PAINTING INSPECTIONSA/ Test report from supplier B/ Client ’s technical requirement Test report and certificate QA, Technical department R 1.2 Test and inspection equipment and measuring device calibration Calibration certificate Instrument record book Calibration certificate QA, Technical department R 2.0 Process control 2.1 Initial production A/ Coating .

Qualification testing is a critical component to coating system selection. This article focuses on performance evaluations that are used to prequalify coating systems, namely, facility-specific, industry-specific, coating-type-specific, or a combination of these. Coatings, an international, peer-reviewed Open Access journal. Journals. Active Journals Find a Journal Journal Proposal Proceedings Series. Topics. Information. . The erosion test is conducted at a 45° angle with 100 m/s velocity using self-developed erosion equipment. The erosion resistance mechanisms of both the substrate and the coating .

The test area is then brushed diagonally five times in each direction to remove any loose film finish particles. A special tape for testing adhesion is then firmly applied over the cross-hatch test area and removed quickly by pulling the tape back off of the test area to reveal the amount of coating lifted off by the test tape. The cross . 4.1 Immersion in water can cause the degradation of coatings. Knowledge on how a coating resists water immersion is helpful in predicting its service life. Failure in a water immersion test may be caused by a number of factors including a deficiency in the coating itself, contamination of the substrate, or inadequate surface preparation.

paints and coatings market size

paint market size chart

webJerkmate. NEW - Watch a video recording of the game. Choose a girl, and command her as you wish! These girls will do anything you like - show their kitty, twerk their ass, insert a .

coating test report|industrial coatings market